FAQ

Barcode

How to Set Up Barcode

-

Download the GRN Barcode Report Template from the links below:

-

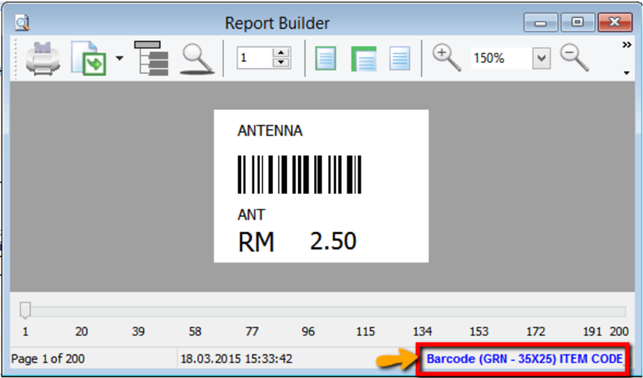

Barcode Capture from Maintain Stock Item Barcode as Barcode.

- Template: GRN BarCode (20×40) Capture Item BarCode

-

Barcode Capture from Maintain Stock Item as Barcode.

- Template: GRN BarCode (35×25) Capture Item Code

-

-

Steps to import the report into SQL Account:

infoRefer to this guide for details.

- Log on to SQL Account.

- Go to Tools > Report Designer > Import.

- Change the file type from Fast Report (*.fr3) to SQL Reports (*.rtm).

- Select the report downloaded in Step 1.

-

Go to Purchase > Goods Received Note > Preview.

- Click on the blue link to enter Report Design.

-

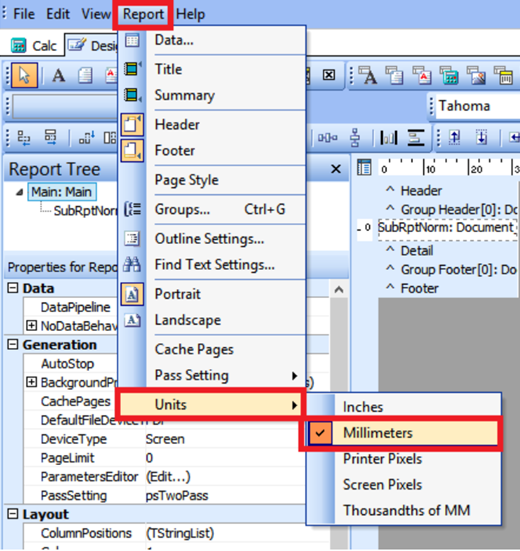

Change the report type to MM because the barcode size is small.

-

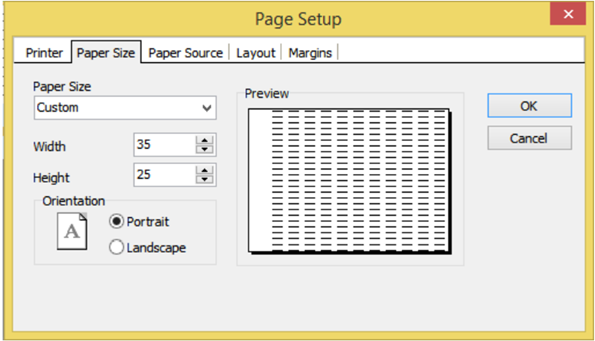

Change barcode size: File > Page Setup > Paper Size.

- Currently, this sample is Width = 35mm, Height = 25mm.

-

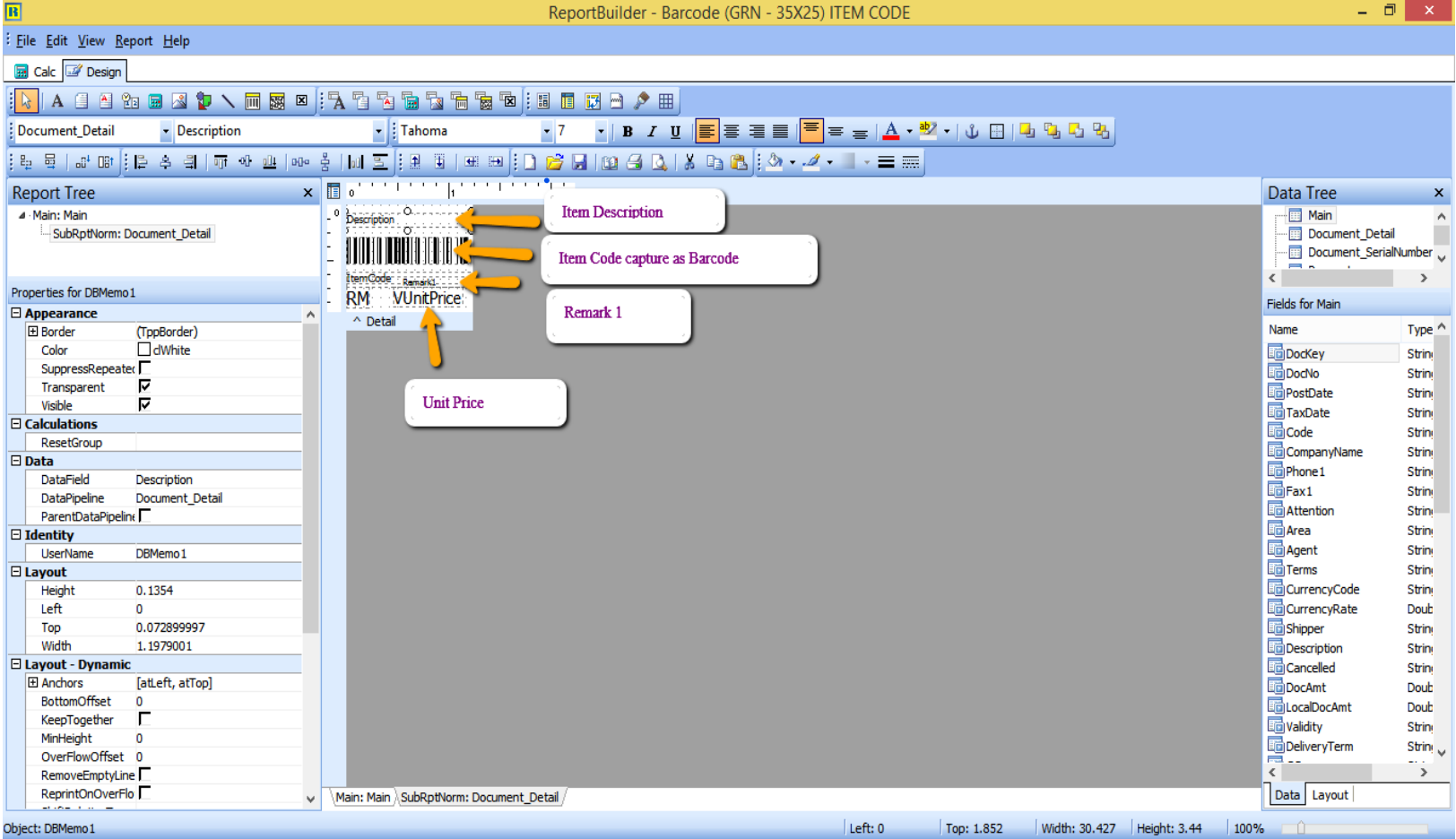

Click on SubRptNorm : Document_Detail.

- From here, you may change the Barcode layout.

-

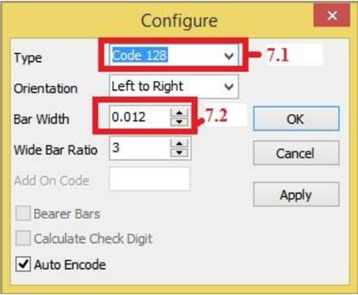

Click on DBBarcode > Right click > Configure.

- Type: Select 128.

- Bar Width: This is the barcode width.

-

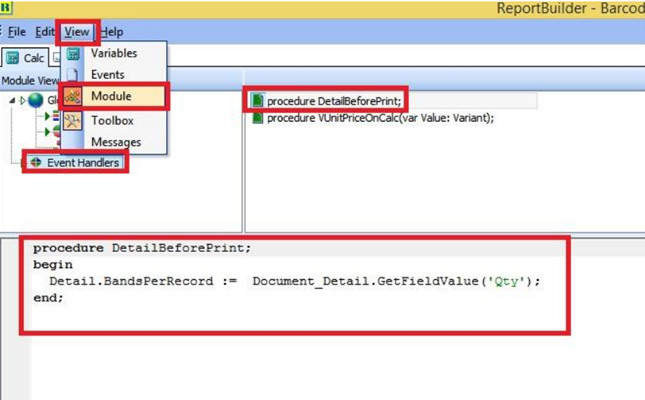

GRN Barcode Event.

- View > Module > Click on Event Handlers > Procedure DetailBeforeDetail.

This step captures the item quantity. For example, if the quantity is 10, it will generate 10 barcode labels.

How to Configure Cash Drawer Settings

- To define the cash drawer settings with a compatible device.

- Tools > Options > Barcode > Cash Drawer.

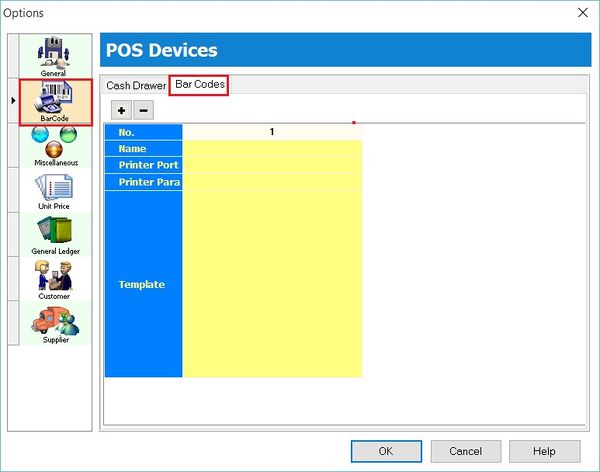

How to Configure Barcode Settings

- To define the barcode settings with a compatible device, e.g., a barcode printer.

- Tools > Options > Barcode > Barcode.

Print Barcode (Direct Printer)

- To print barcode labels using a Special Barcode Printer for items created in Maintain Stock Item.

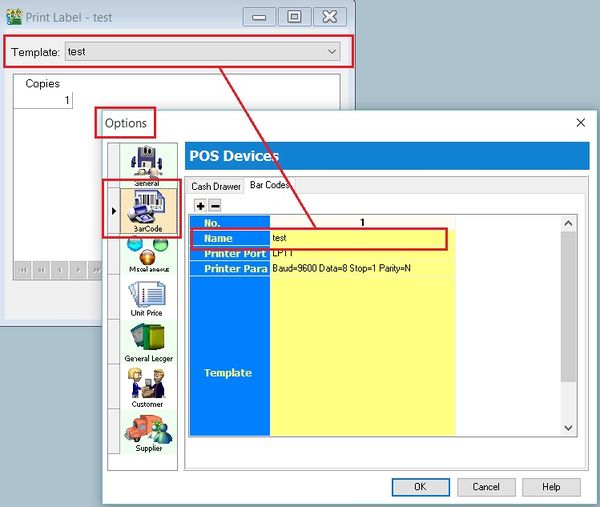

How to Configure Barcode Printer Settings

-

Tools > Options > Barcode > Barcode.

-

Insert the new barcode printer setting and template.

-

Click OK to exit.

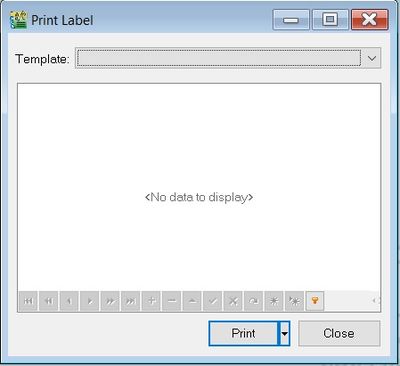

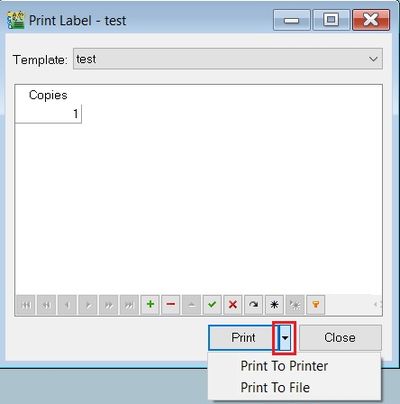

How to Print the Barcode Label

- Click on the arrow beside the Print button. See the screenshot below.

- You can choose either Print to Printer (barcode printer) or Print To File (output as text file).

Print Barcode (Windows Printer)

- To print barcode labels using a Windows Printer for items created in Maintain Stock Item.

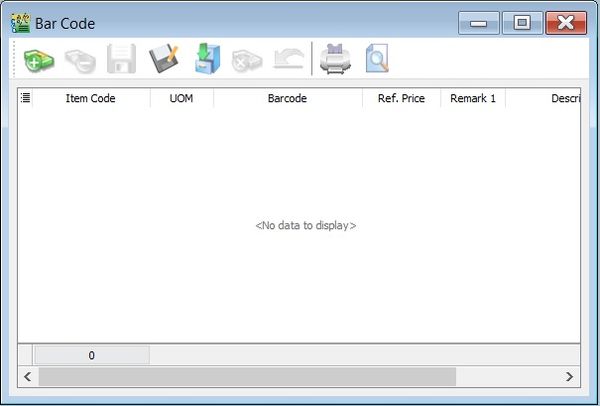

How to Update Item Barcode Listing

-

First, update the item barcode in Maintain Stock Item.

-

Click the + button to insert items. See the screenshot below.

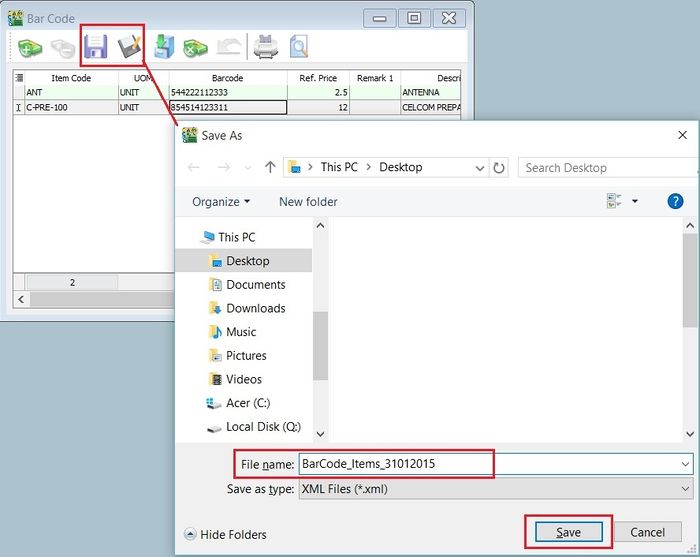

-

Click the SAVE button to save the item barcode listing. Type a file name (e.g., BarCode_Items_31122015) to save. See the screenshot below.

-

A message will prompt. Click OK.

How to Load a Previous Item Barcode Listing

-

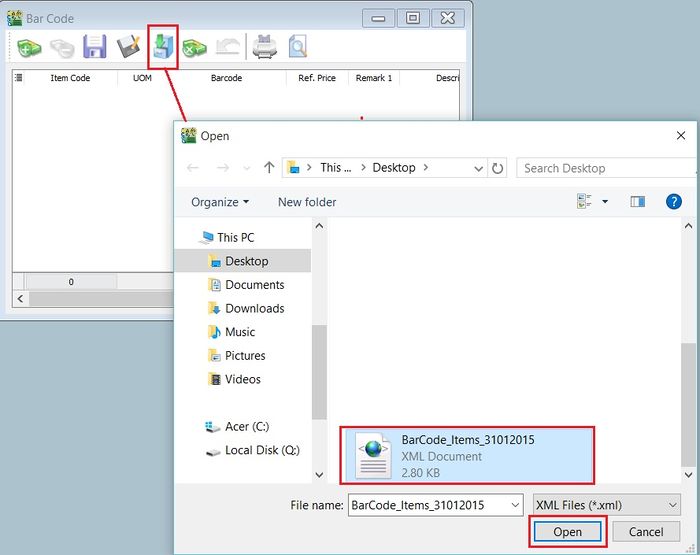

Click on the Cabinet button to load the previous file for the item barcode listing (e.g., BarCode_Items_31122015). Click OPEN.

-

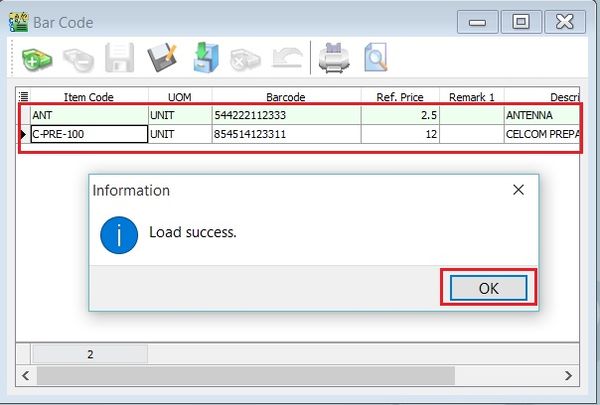

A confirmation message will prompt. Click OK to load it. Click NO to cancel.

-

A "Load success" message will prompt. Click OK to proceed.

-

You can continue updating new items and save as a new file name.

How to Preview/Print the Barcode Label

-

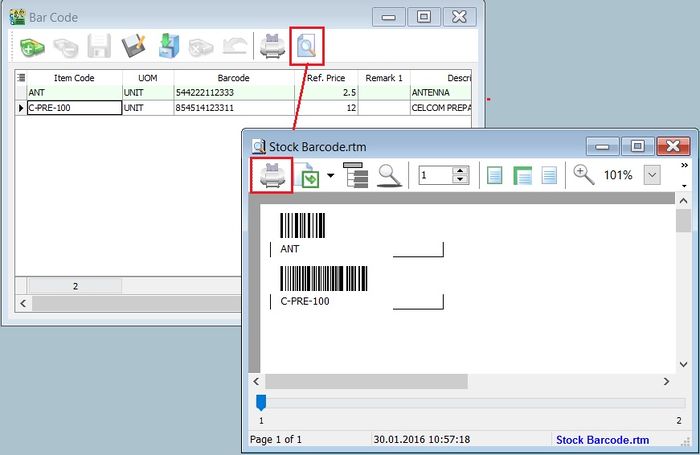

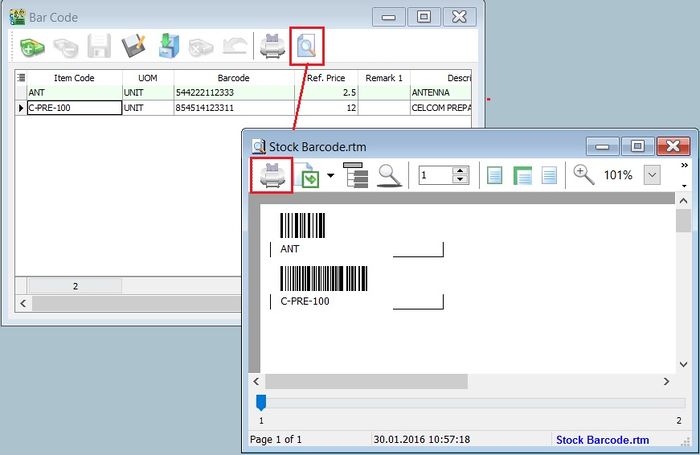

Click on Preview or Printer (to skip the preview).

-

After the preview, click the Printer button to print.

How to Change the Label Size (mm) Measurement for the Barcode Label

-

Click on the Report Name. See the screenshot below.

-

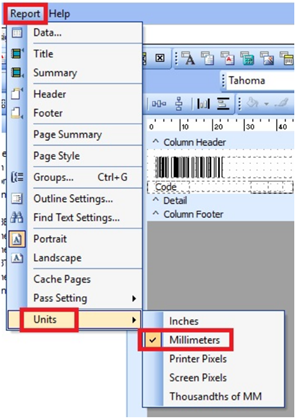

To change the paper unit measurement, click on Report > Units, and choose Millimeters.

-

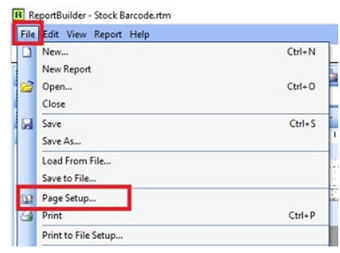

To change the paper size, click on File > Page Setup...

-

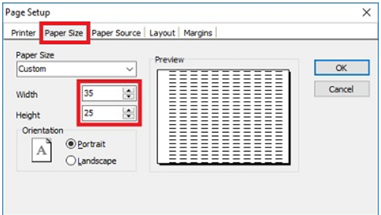

Click on the Paper Size tab, change the Width and Height to 35 and 25 respectively (mm), e.g., the label paper size is 35mm x 25mm.

-

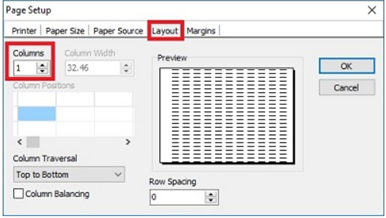

Check the Layout tab to make sure Columns is set to 1.

-

Check the Margin tab as well to make sure all (Top, Bottom, Left, Right) are set to 0. Click OK to exit Page Setup.

-

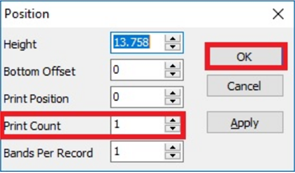

To ensure each page contains 1 barcode of an item, right-click on the Detail band and select Position.

-

Set Print Count to 1. Click OK to confirm.

-

Save the report with another name.

Stock (Inventory)

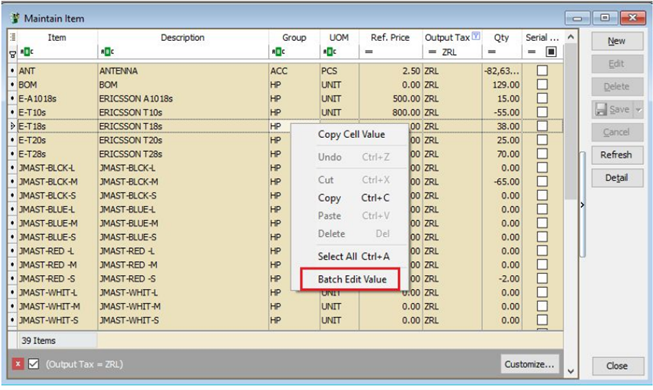

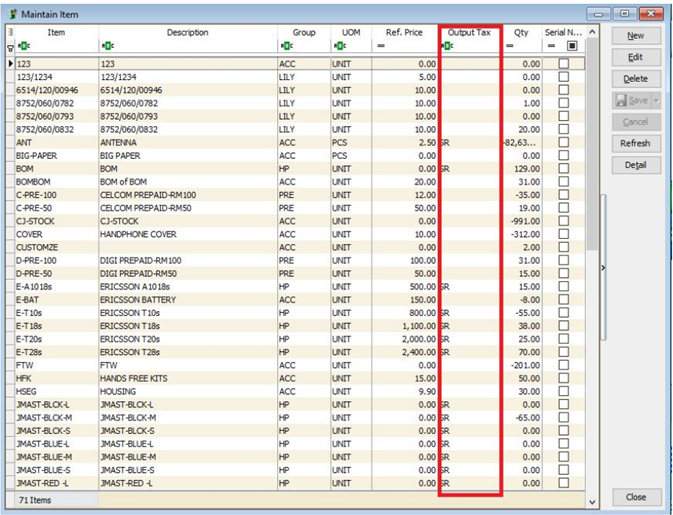

How to Batch Edit Values in Maintain Stock Item

Allows you to update/edit field values in batches.

-

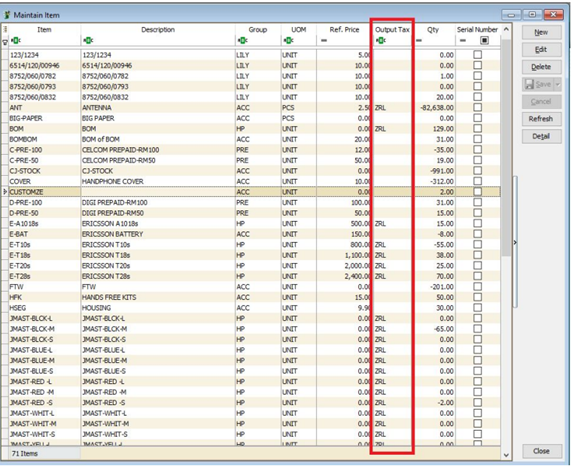

Go to Stock > Maintain Stock Items.

-

For example, change the output tax code from ZRL to SR for ZRL items only.

-

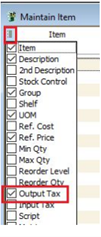

Click on the first column (beside the item column).

-

Drag out the Output Tax column.

-

You will see the Output Tax column as shown in the screenshot below.

-

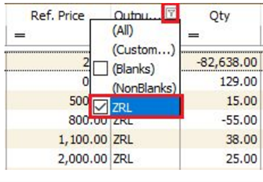

Click on the Output Tax filter.

-

Tick ZRL. All ZRL items will be filtered.

-

Press Ctrl + A to select all ZRL items.

-

Right-click on the highlighted items. Click on Batch Edit Value.

-

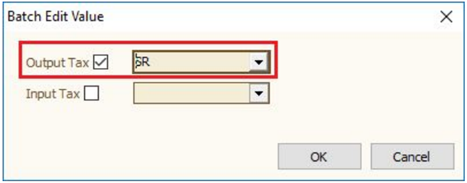

Tick Output Tax and select the tax code (SR).

-

Click OK to proceed with the changes.

-

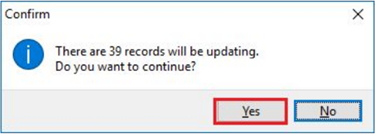

Click Yes to confirm the update.

-

Click OK.

- Result

Items with the default output tax previously set to ZRL are successfully changed to SR.

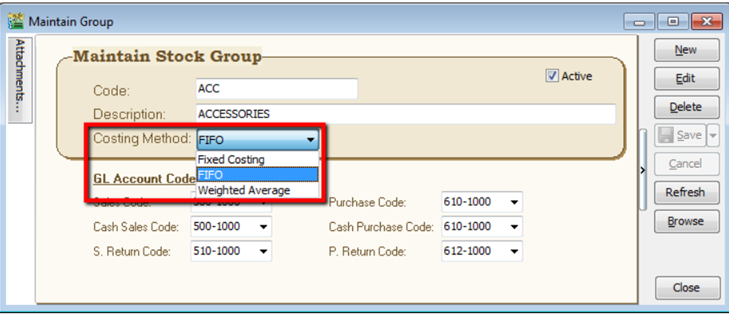

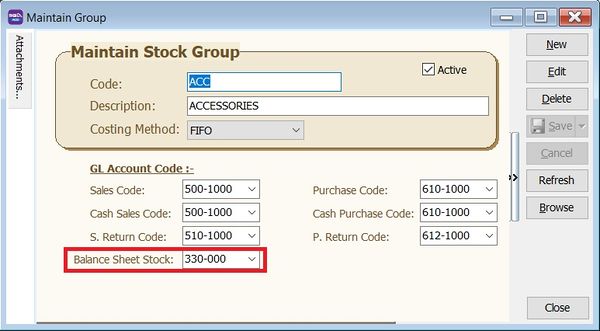

How to Set Up Costing Method

-

Go to Stock > Maintain Stock Group.

-

There are 3 methods you can assign:

- FIFO - Cost flow assumption that the first goods purchased are also the first goods sold.

- Fixed Costing – Fixed cost maintained under Maintain Stock Item.

- Weighted Average - Average cost of production for a product.

-

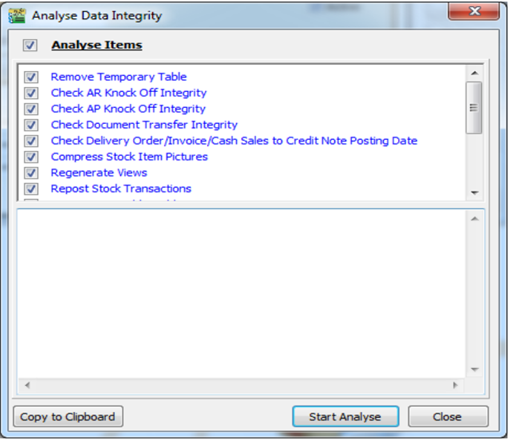

If you change your costing method (with existing transactions):

- Please remember to run Analyse Data Integrity (Tools > Analyse Data Integrity) before checking the costing report again.

tip

tipThe system will automatically update transactions from the first date until the current date with the new costing method.

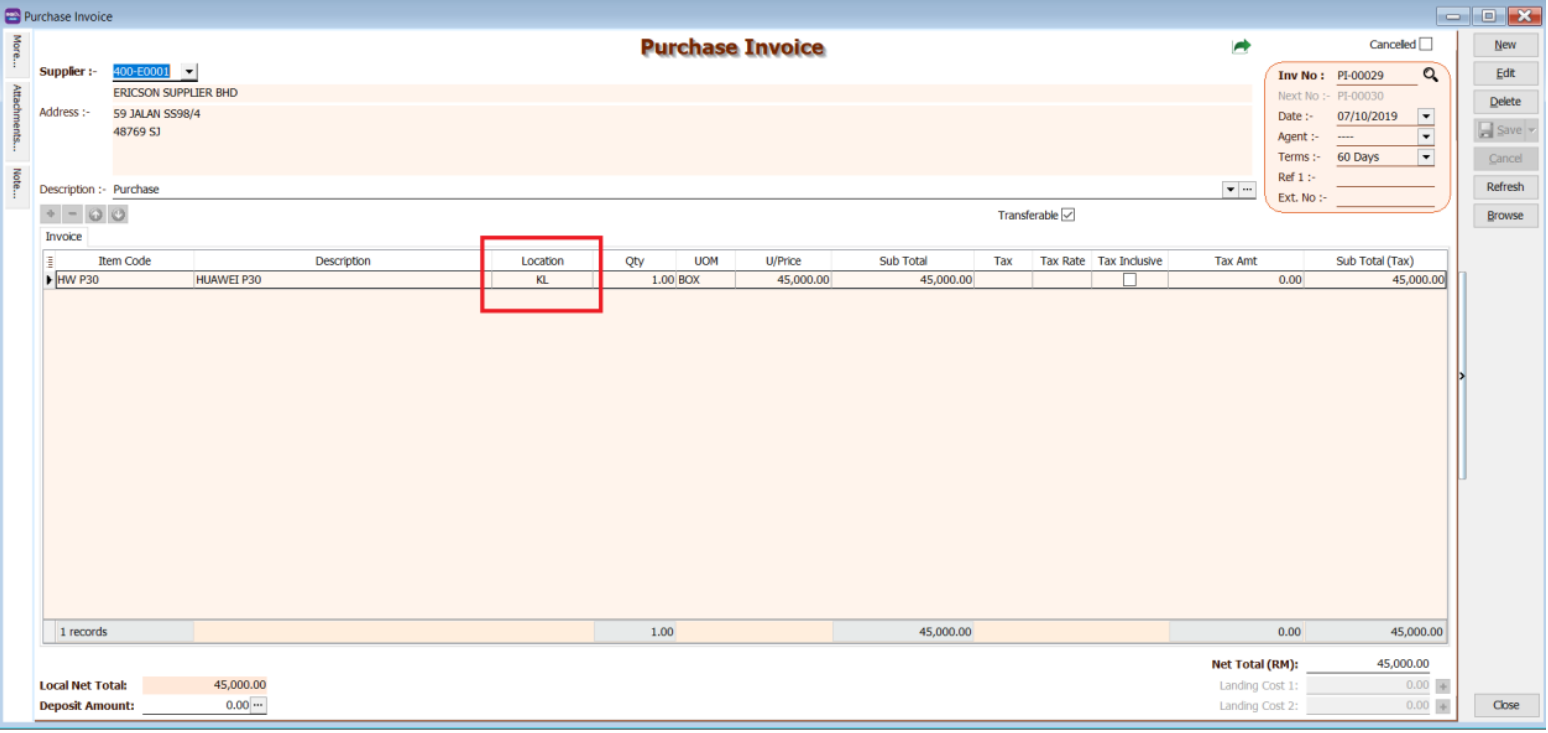

Multi Location Module

- This module is used to manage multiple warehouses, inter-branch transfers, consignment, van sales, etc.

How to Set Multiple Warehouses

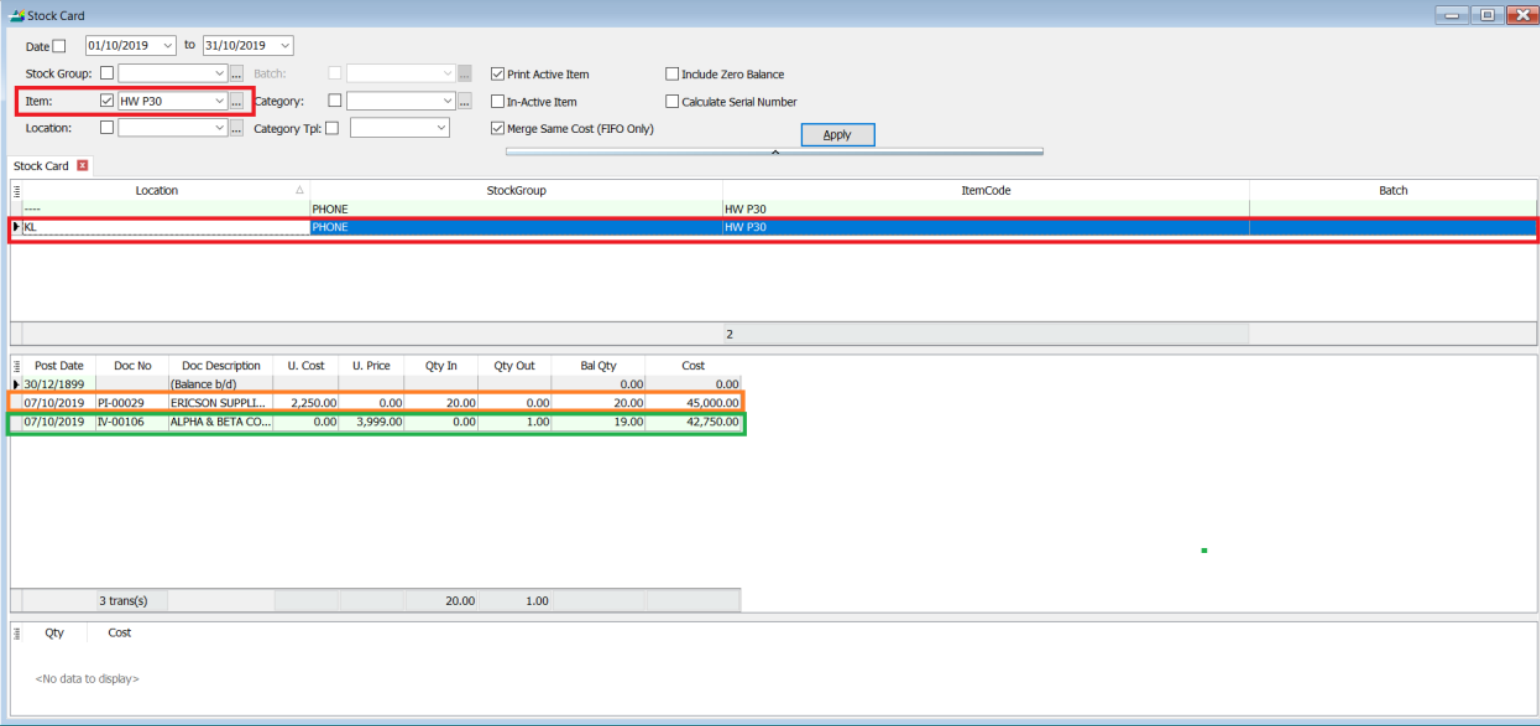

HQ is helping the KL branch to order goods, and the goods shall be sent to the KL branch warehouse.

-

When purchasing items from a supplier, you may choose your branch warehouse (KL) as your location in the purchase invoice.

-

When you sell the item, you may choose the location to sell from the branch warehouse (KL).

-

You will see stock in to the branch warehouse (KL) and stock out from the branch warehouse (KL) when you check your stock card report.

From the stock card report, you can see the item is stored in two locations: one is Default, and one is KL. The stock in and out transactions you performed will be reflected in location KL.

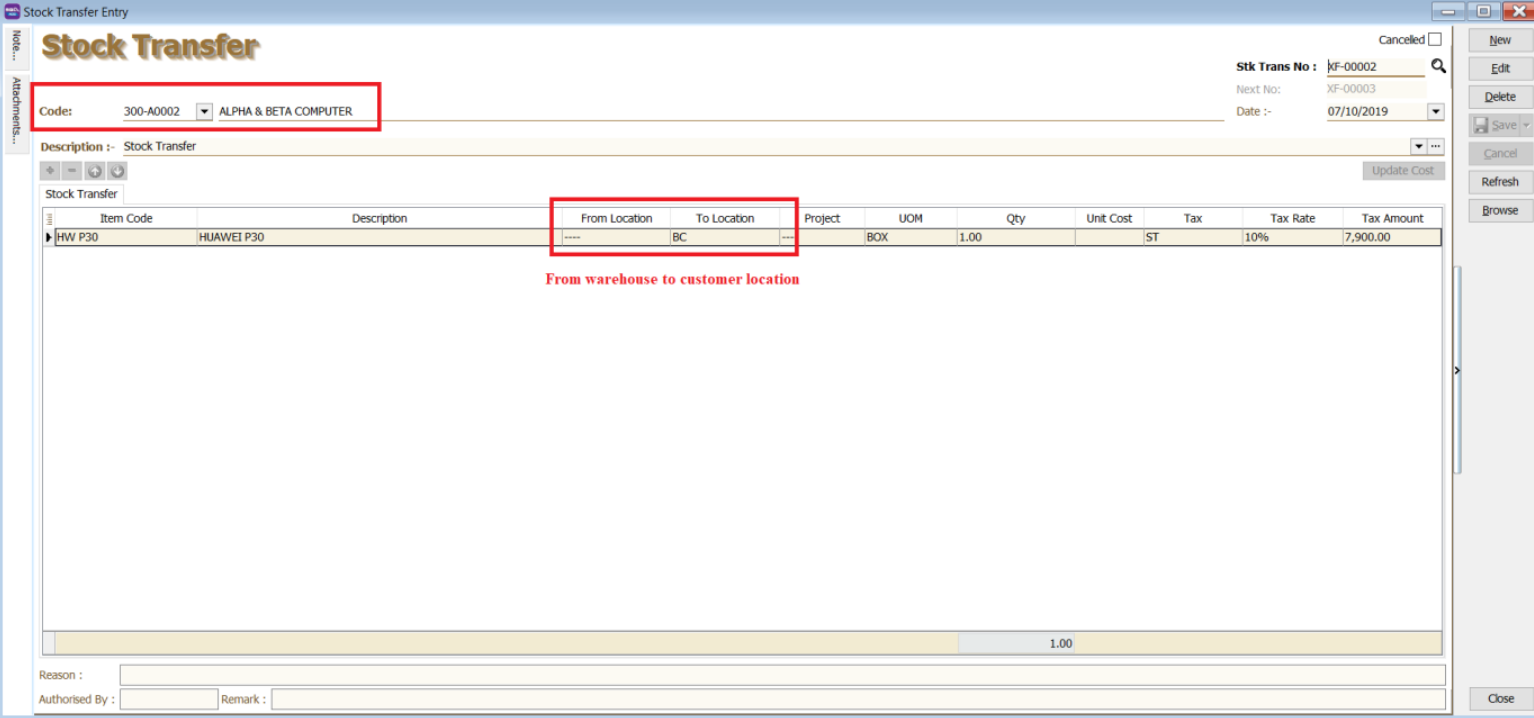

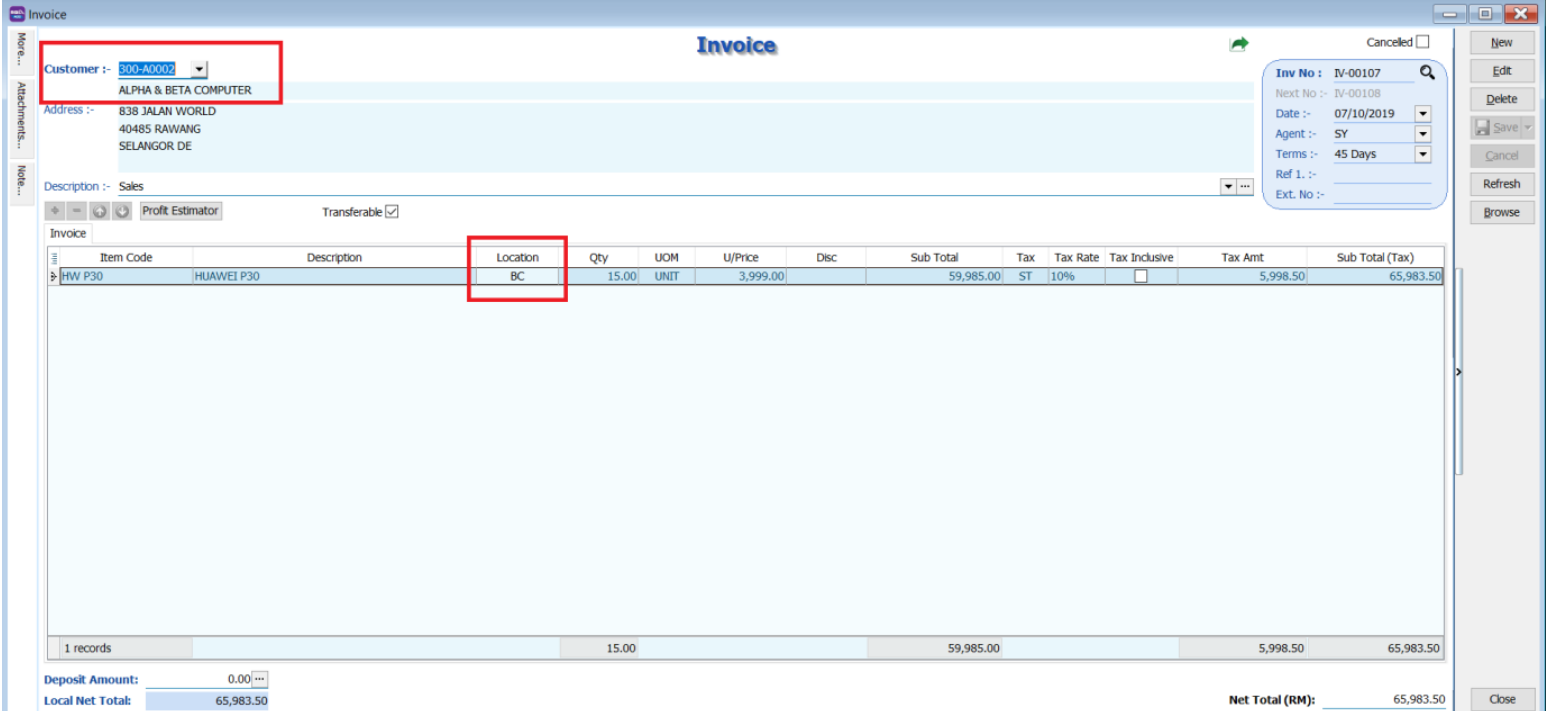

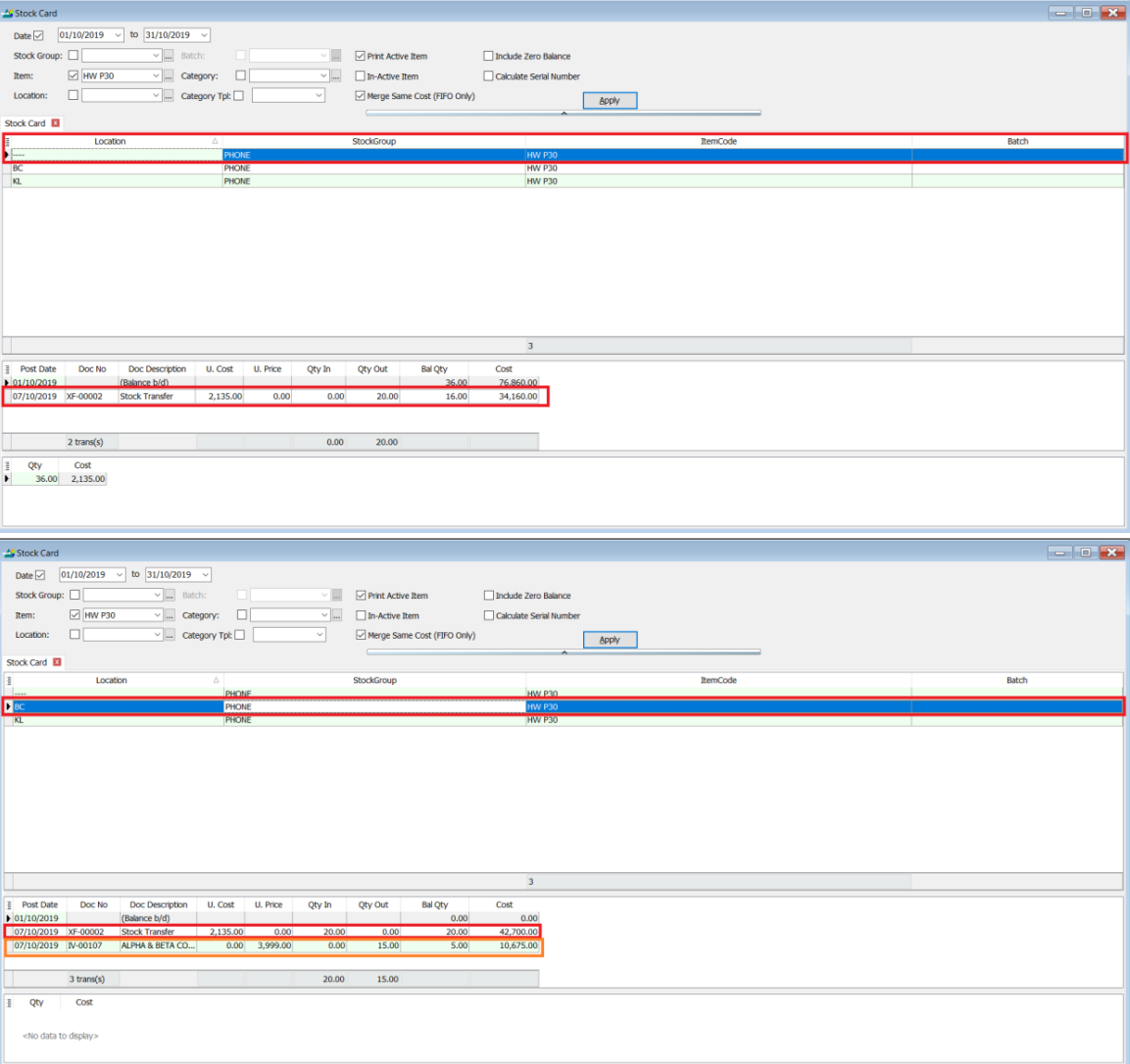

How to Do Consignment

A batch of goods is consigned to your customer for selling without billing first. You will only bill them after they sell the goods.

-

Open a stock transfer document to transfer the goods from your warehouse (Default) to the customer warehouse (Batu Caves).

-

The customer receives 1 box of goods (20 units) and sells 15 units. Then you can bill the customer for 15 units, where the goods are deducted from the customer location (Batu Caves).

-

You will see stock transferred out from your warehouse (Default) and into the customer warehouse (Batu Caves).

From the stock card report, you can see the item is sold out from your customer location (Batu Caves) after you create the billing.

Stock Adjustment & Stock Take

- Allows users to key in quantities in and out of the system, similar to a combination of stock received and stock issued. It is normally used for stock-taking purposes. (Stock > Stock Adjustment > New).

How SQL System Can Help During Stock Take

-

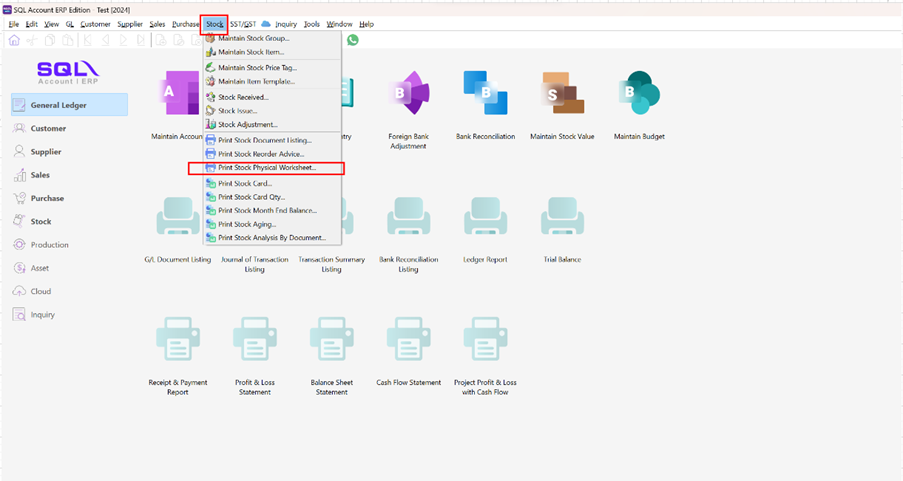

Go to Stock > Print Stock Physical Worksheet.

-

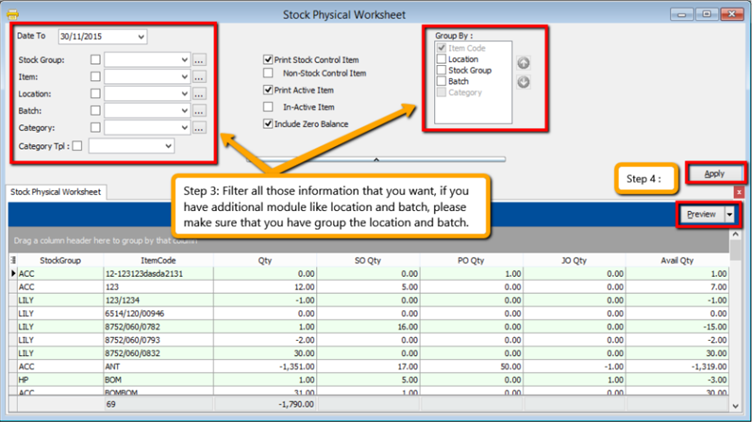

Filter by date, stock group, or other information for the stock take. Please ensure that you have chosen the correct location and batch if you have these 2 modules.

-

Click on Apply and Preview.

-

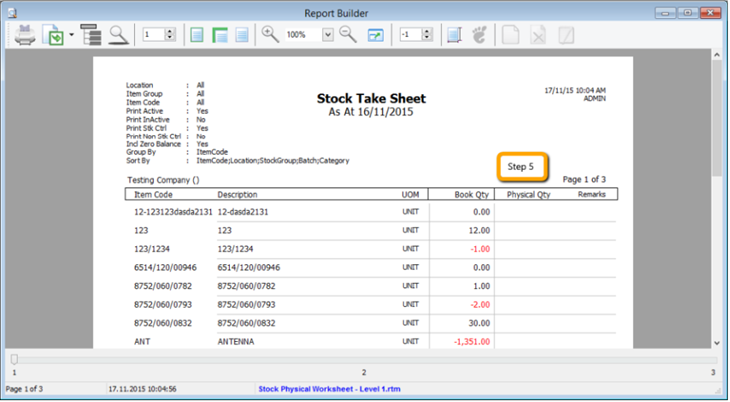

Print out this Stock Physical Worksheet (Stock Take Sheet) for the storekeeper to manually fill in the actual stock physical quantity at the warehouse. The storekeeper just has to fill in the actual quantity into the Physical Qty column.

-

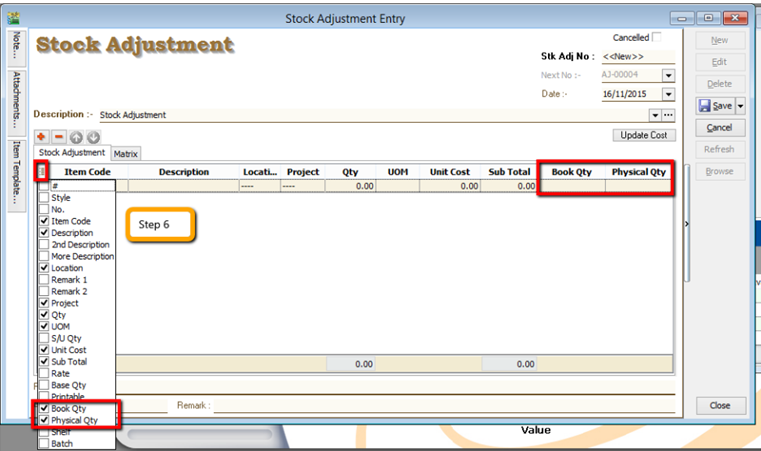

After completing the stock take report, go to Stock > Stock Adjustment > Drag Out Book Qty and Physical Qty.

-

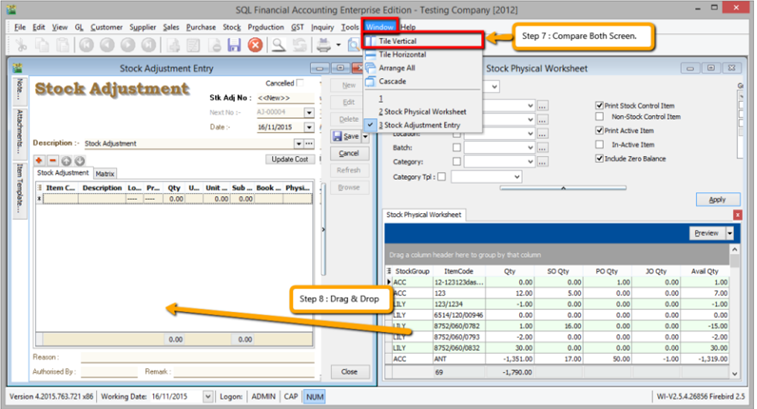

Repeat Steps 1 & 2 to call out the Stock Physical Worksheet again. Open 2 screens simultaneously: one for Stock Adjustment and another for Stock Physical Worksheet. Then click on Window > Tile Vertical.

-

Click on the first item in Stock Physical Worksheet, press Ctrl + A on the keyboard to select all items. Then Drag & Drop into Stock Adjustment.

-

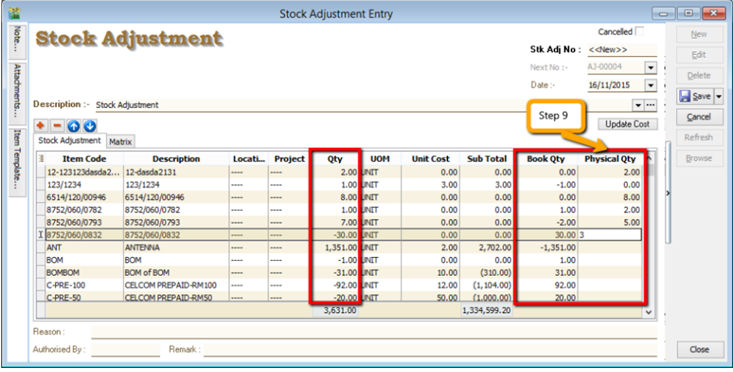

Based on the storekeeper’s Stock Take Report, fill in the actual physical quantity in your warehouse into the Stock Adjustment Physical Qty column. The system will calculate the variance based on the Book Qty and apply it to the Qty column.

Book Qty = Quantity recorded in the system.

Physical Qty = Actual Quantity at your warehouse.

Qty = Variance between Physical and Book Quantity. The system will automatically adjust and update accordingly. (Physical Qty – Book Qty)

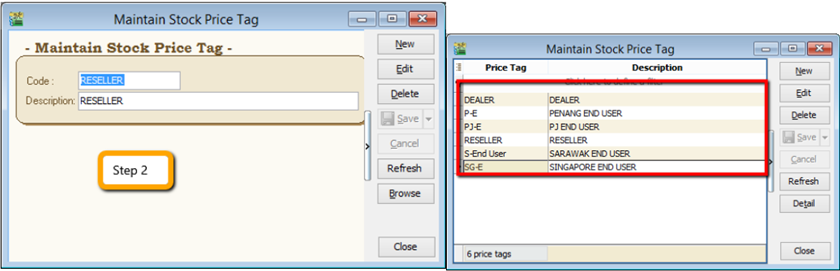

Stock Price Tag Module

- This module is mainly used to set different pricing groups for different customers and suppliers. It is normally used to set different customer categories with different pricing. To apply individual customer pricing, you can group your customers into different price groups.

How to Set Up Price Tag

-

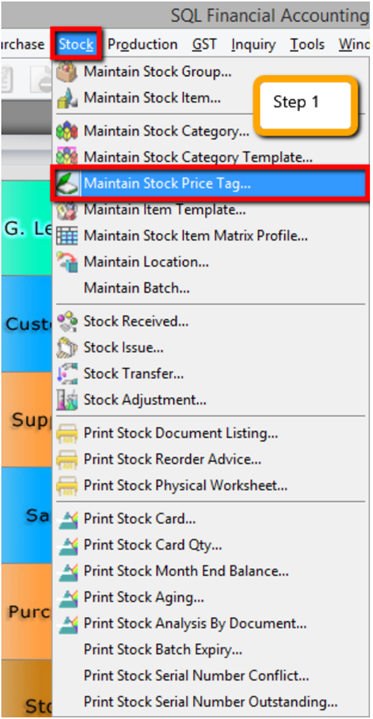

Go to Stock > Maintain Stock Price Tag.

-

Create a category for the customer you want.

-

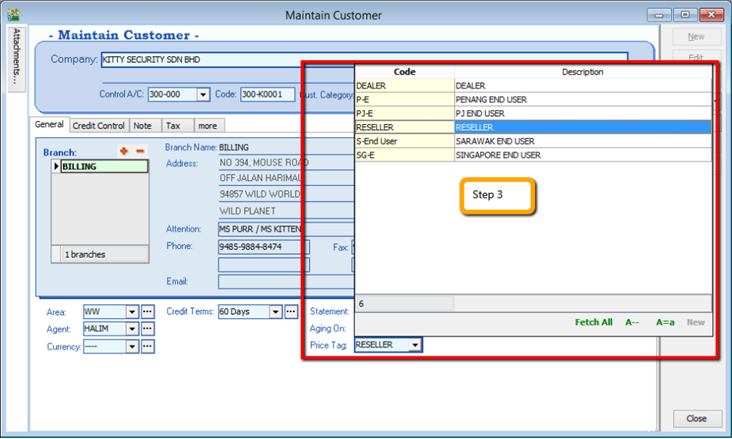

Edit Customer Price Tag.

- After creating the customer category in Maintain Stock Price Tag, click on Customer > Maintain Customer > Edit the Price Tag and assign it accordingly.

-

Assign Customer Price Tag.

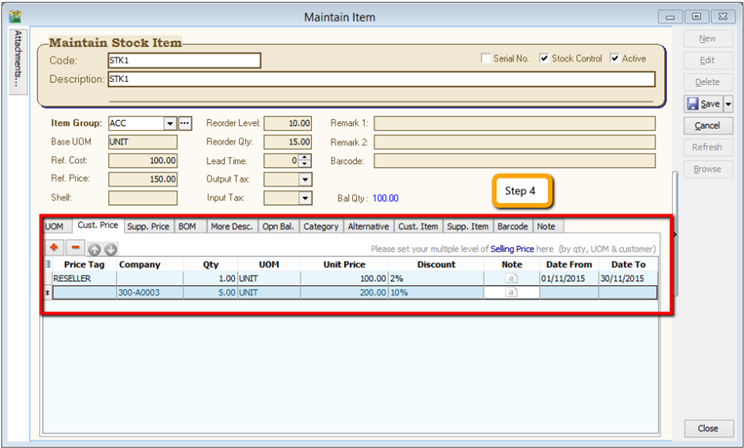

- Click on Stock > Maintain Stock Item > Edit and click on the Cust Price Tag, then assign accordingly.

info

info- Price Tag: Select the price tag group you assigned under Maintain Customer.

- Company: Besides the price tag, you can set specific pricing for an individual customer.

- Qty & UOM: You can define the quantity to which you want to apply the price.

- Unit Price: The unit price you want to offer for those customers.

- Discount: You can follow the original unit price but give a discount, e.g., 5% or RM 5.

- Note: Additional remarks you can record, like "Year End Sales Promotion".

- Date From & Date To: The price validity date.

-

Repeat the same steps for Supplier if you want to apply it to the Supplier Price.

Reorder Lvl & Qty

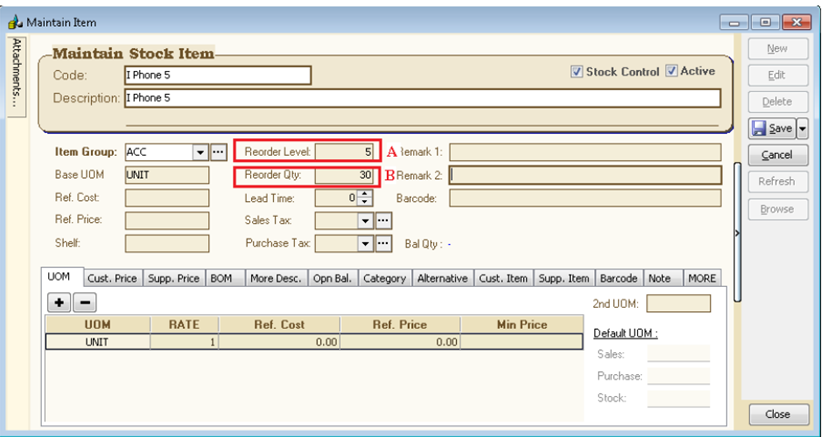

How to Set the Reorder Level

Reorder level (or reorder point) is the inventory level at which a company would place a new order or start a new manufacturing run.

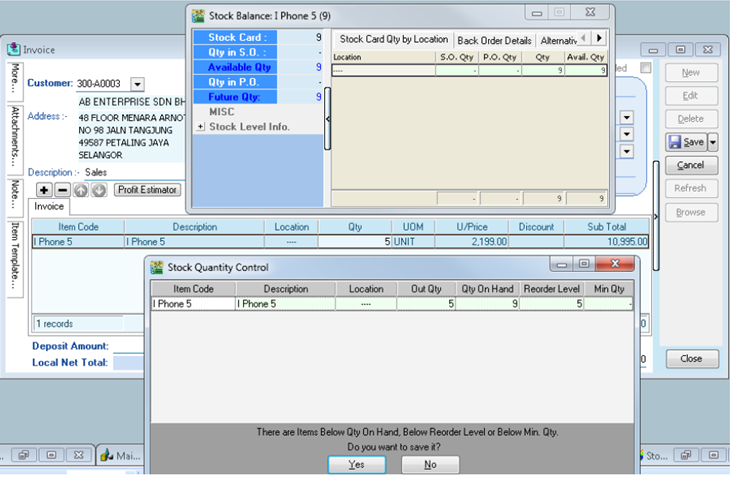

Example:

- For this item, Reorder Qty = 5. When Bal Qty is less than 5 units (e.g., 9-5 = 4), saving the document will prompt a dialog (Stock Quantity Control) to remind you to place an order.

The Stock Quantity Control dialog can be turned on via Tools > Options > Miscellaneous > Prompt Negative Stock Quantity Dialog Box > Checked.

How to Set the Reorder Qty

Reorder quantity is the point at which a business must buy more inventory so as not to run out of stock.

How to check if stock is running below the reorder level?

- Stock > Print Stock Reorder Advice > Select any criteria if applicable > Apply.

Criteria A: Options available:

- On Hand Qty

- On Hand Qty + PO

- On Hand Qty – SO

- On Hand Qty + PO – SO

VS

- Reorder Level

- Min Level

- Max Level

There is a faster way to create a Purchase Order (PO) with Reorder QTY. Please see the screen below:

Steps:

- After getting the appropriate result from Reorder Advice, click on the First Item, press the Shift Key (Keyboard), and click on the Last Item.

- New PO > Select Supplier > Drag from Reorder Advice to PO Itemize (as per picture). PO Qty = Reorder Qty.

Serial No Module

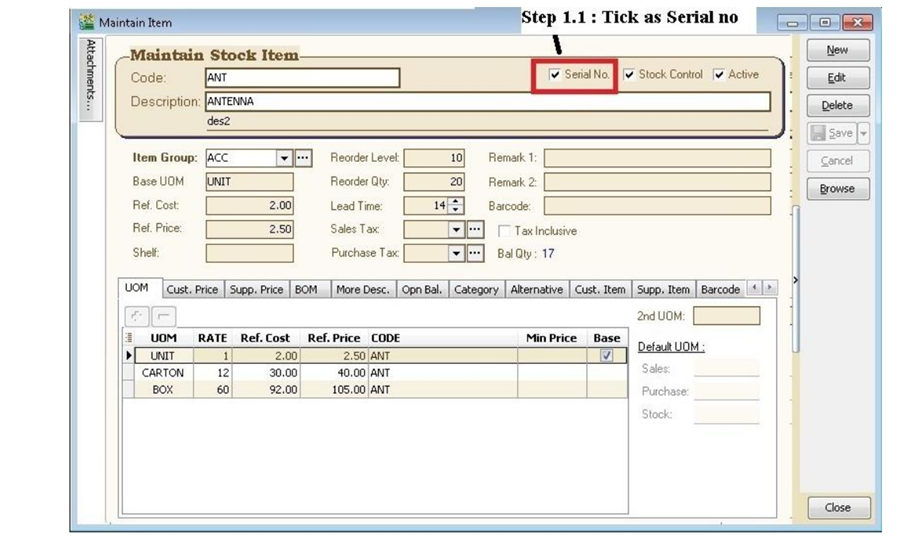

How to Set Up Control Serial Number

-

Go to Stock > Maintain Stock Item > Edit > Check Serial No if you would like to control the serial number for this item.

-

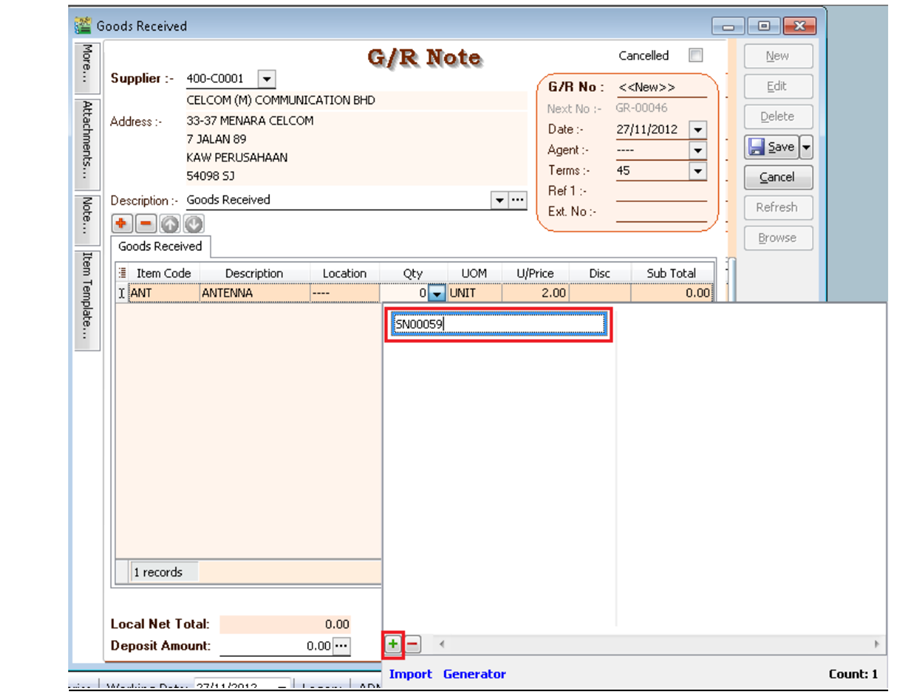

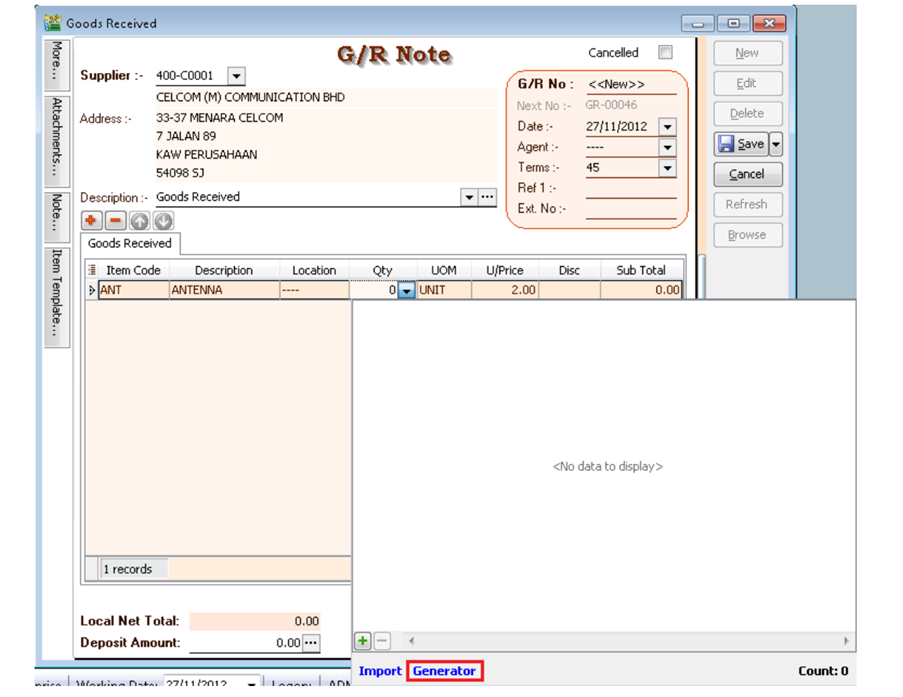

Purchase > Goods Received Note > New.

There are 3 methods to apply serial numbers:

- Method 1: Manually Enter

-

Click on + (Green Icon) > Manually Enter in the Empty Box.

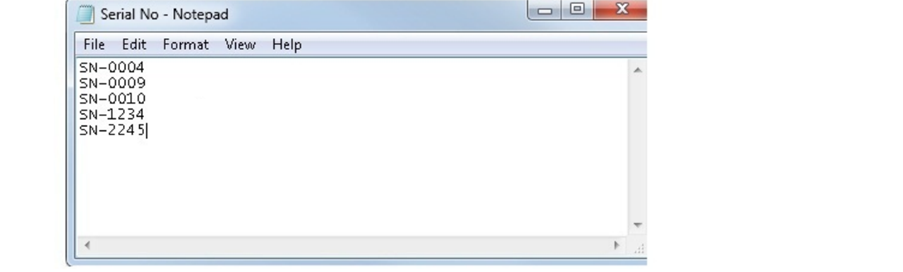

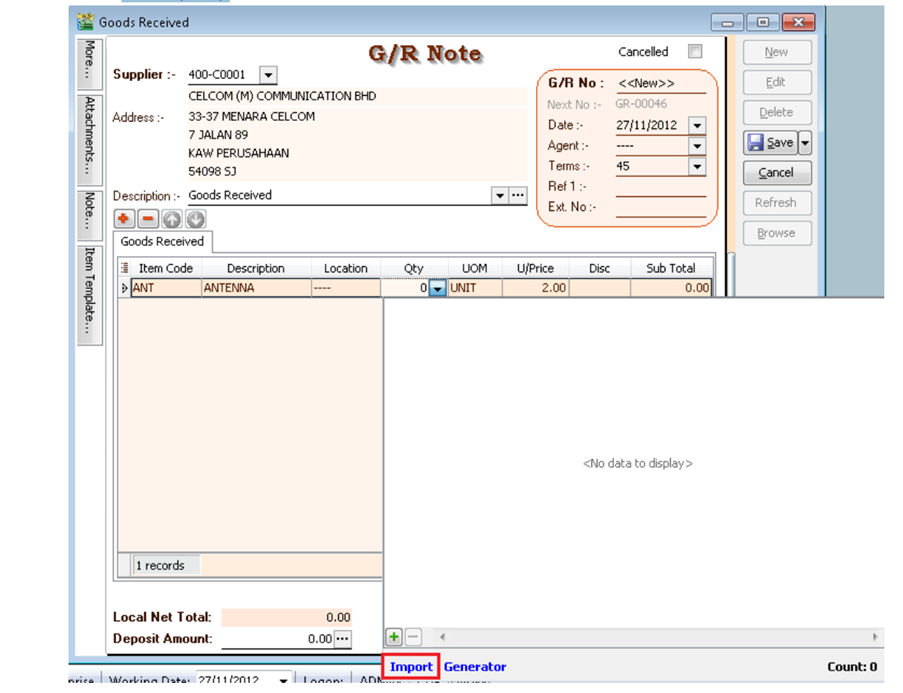

- Method 2: Import from Notepad / Word

-

Enter the Serial No in Notepad.

-

Click Import.

-

Select the Notepad file where you saved it.

-

Click OK.

- Method 3: Generator

-

Click on Generator.

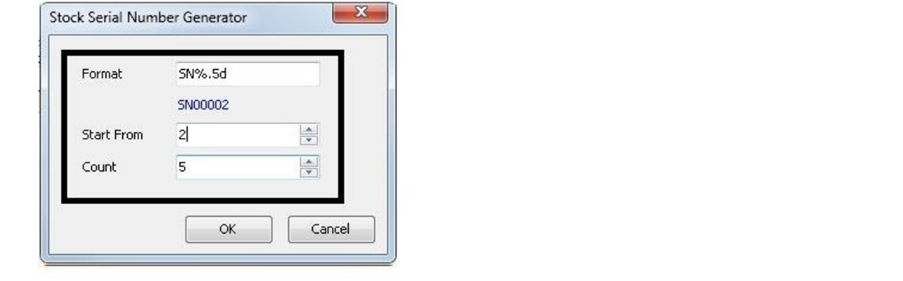

-

Format = Serial No Format.

Start From = What number you wish to start from.

Count = How many units to generate.

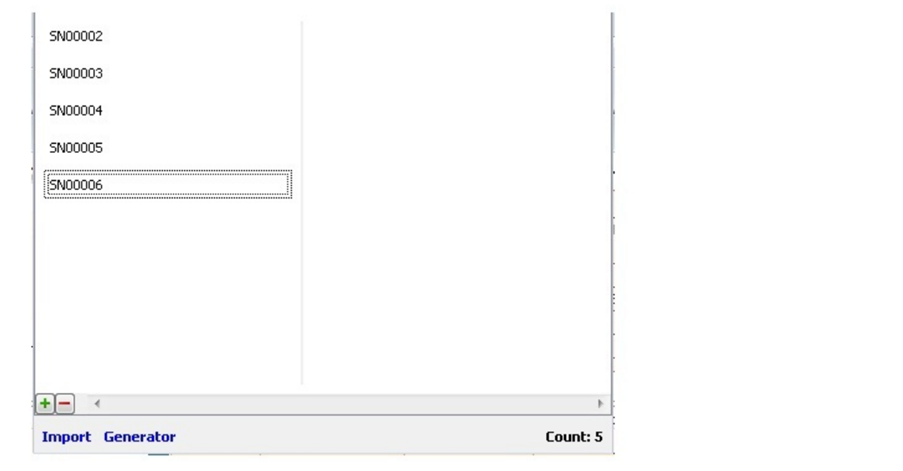

-

Here is the output.

-

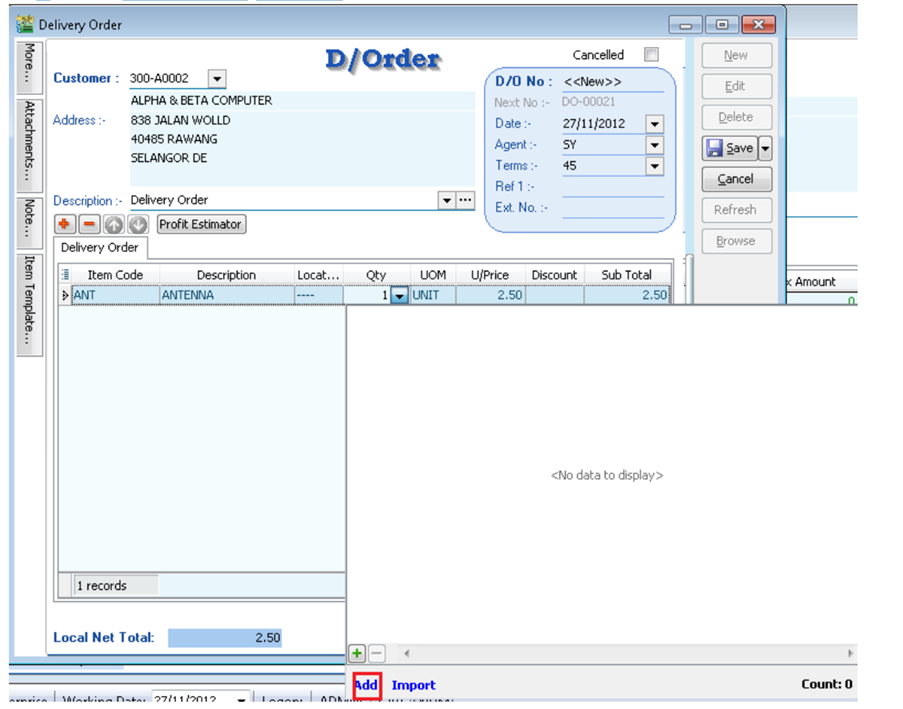

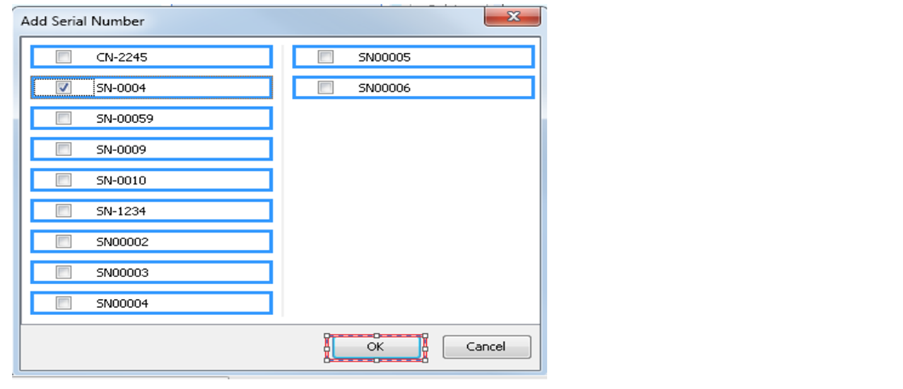

Sales > Delivery Order > Click Add.

+ (Green Color) Same method as Method 1. Import same method as Method 2.

-

Tick Serial No > Press OK.

Stock Adjustment does not support serial numbers. You may use Stock Received and Stock Issue as a replacement.

Serial No Report

-

Stock > Print Stock Physical Worksheet – Will show all balance serial numbers that haven't been used.

-

Stock > Print Stock Card - Tick Calculate Serial Number before applying.

NoteChecked Calculate Serial No > Only Report : Stock Card – Location

-

Stock > Print Stock Month End Balance – Tick Calculate Serial Number before applying.

-

Stock > Print Stock Serial No Conflict

- To check non-existent Serial No. Example: Purchase for this Item has serial number 555666, but when stocking out, the serial number is 222333.

- To check duplicate Serial Numbers received at the same location/batch for the same item. If returned to stock with the same serial number and out again, it will not be considered a conflict.

-

Stock > Print Stock Outstanding Serial No.

- For those documents Issued or Received without applying a serial number.

-

Inquiry > Print Serial No Inquiry.

- Check serial no movement.

-

Sales > S/N Profit & Loss by Document.

- This Report Cost captures exactly from Stock In Serial Number Cost. If DO transfers to IV, because DO has deducted the Serial number, there will be no result for this report.

How to Use Access Rights for Serial No

-

Group Stock > Always match Qty with Serial No.

- This access right means the serial no must match the Qty keyed in. E.g., 2 Qty must have 2 Serial Nos.

- If this right is checked, Print Outstanding Serial No will show no results.

-

Allow Non-Existent Serial No.

- This access right controls whether to allow stocking out a serial number without matching the serial number from purchase. Example: Purchase for this Item has serial number 555666, but when stocking out, the serial number is 222333. If you do not allow this, you may uncheck this access right.

- If this right is unchecked, Print Stock Serial No Conflict will show no results.

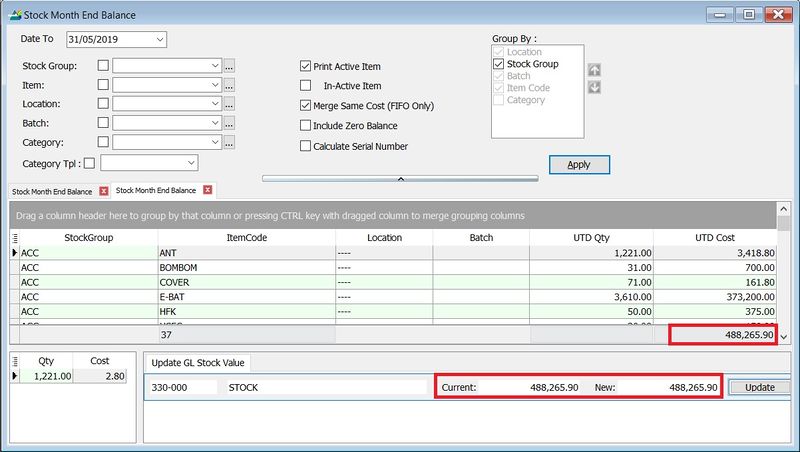

Stock Month End Balance

Why can't I update the GL Stock Value at Stock Month End Balance?

-

Issue

-

Click the Update button at Stock Month End Balance, but no stock value is updated to GL Maintain Stock Value.

-

Solution

-

Ensure all stock groups have defined a Stock Account.

-

Apply the Stock Month End again and click the Update button.

-

GL > Maintain Stock Value... Stock Value is now the same as Stock Month End Balance.